«Bioconversion of CO2 into High-added Value Bioproducts through Sustainable Microalgae Cultivation Processes», CO2-BioProducts, www.co2-bioproducts.gr Funded by: EYDE-ETAK, EPAnEK (Ministry of Education, Research and Religious Affairs), 2018 – Today

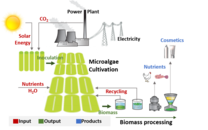

Microalgae biomass is a primary renewable resource for the production of multiple bioproducts, within the operational framework of a 3rd generation biorefinery. If implemented simultaneously with the capture and conversion of significant amounts of CO2 from gas pollutants, this practice can have a large positive environmental impact. The CO2-BioProducts project aims to produce and recover high value bioactive and biochemical products, derived from microalgae biomass.

The central objectives of the CO2-BioProducts is to produce high-added value bioproducts through the bioconversion of available, from power generation plants, CO2, using microalgae. The proposed technology is developed in order to recover from the microalgal biomass bioactive compounds (e.g., phycocyanin, carotene, vitamins), with applications in cosmetics and as high nutritional value ingredients, as well as to fully exploit the residual biomass (rich in proteins, carbohydrates and fatty acids) as livestock feed additive.

The development and implementation of a dual target strategy (profitable production and minimum environmental footprint) is the fundamental principle that is applied to all bioprocesses in order to ensuring the sustainable operation of the complete value chain.

The individual objectives of the project can be summarized as follows:

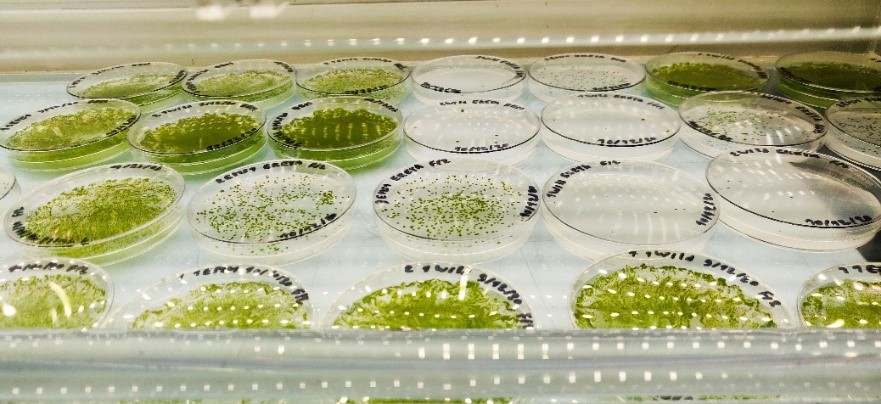

- The selection and optimization of appropriate microalgae strains, giving emphasis to relevant strains already used in industrial applications and by evaluating available strains from two Greek collections. The final objective is the optimization of the most promising strains. An important selection criterion is the tolerance of the investigated strains to the CO2 gaseous effluents and the possible presence of other gaseous pollutants and/or particulates, with the simultaneous presence in the biomass of different cyanotoxins.

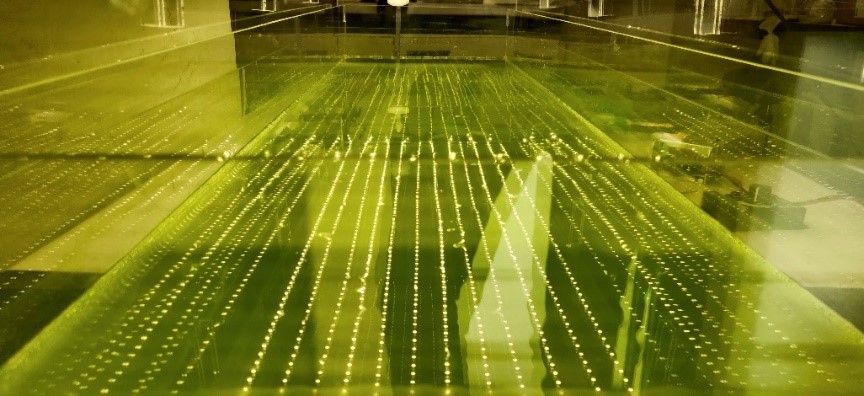

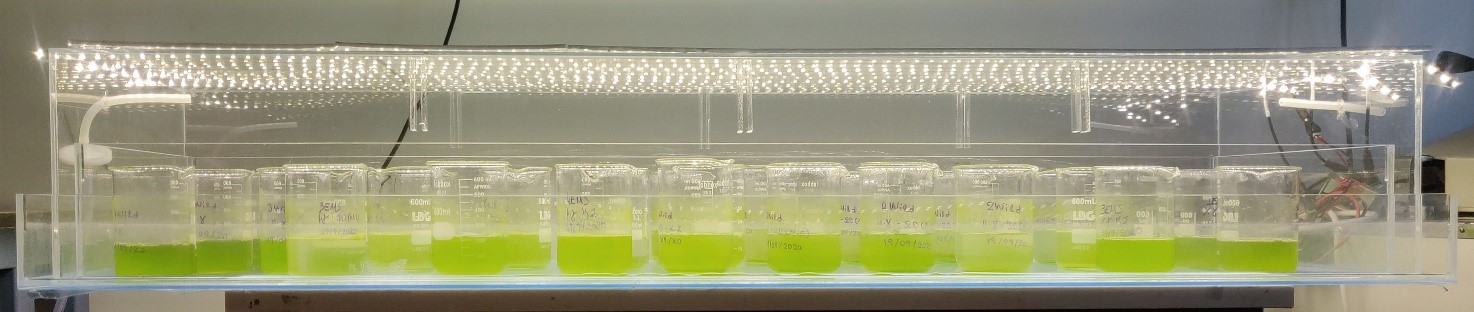

- The optimization and upscale of photo-bioreactors (PBR) in order to maximize the bioconversion of CO2, the utilization of the illumination energy and biomass production rate, as well as to minimize the production cost.

- The control of biomass composition, upon the identification of the cultivation conditions and the operational parameters that favor the maximization of the biomass content in terms of targeted bioactive and biochemical products, via a well-defined statistical Design of Experiments (DoE).

- The optimization of the recovery methods, with the aim to minimize the economic and energy requirements of the biomass fractionation and the recovery of bioactive compounds stages, through the application of innovative primary (immobilized cells) and secondary (enzymatic fractionation) processes.

- The complete characterization (quantitative and qualitative) of microalgal biomass and recovered bioproducts, based on targeted applications: bioactive activity for cosmetic products, nutritional value, etc.

- The efficient scale-up of the integrated process, via a dynamic utilization of the optimized bioprocesses at the industrial level. In addition, following the concept of the zero-waste circular economy, the entire biomass, as well as, useful extracellular components (e.g., polysaccharides) are being exploited.

- The sustainability analysis of the integrated value chain through the implementation of appropriate technical, economic and life-cycle analysis (LCA) studies, in order to identify additional optimization 'hot-spots' from an economic, energy and environmental point of view. Finally, a business plan for the commercial exploitation of the new products is being developed.

ERROR: Content Element with uid "50170" and type "gridelements_pi1" has no rendering definition!

ERROR: Content Element with uid "50163" and type "gridelements_pi1" has no rendering definition!